- HOME

- Machinery & Rolls Division

- Products

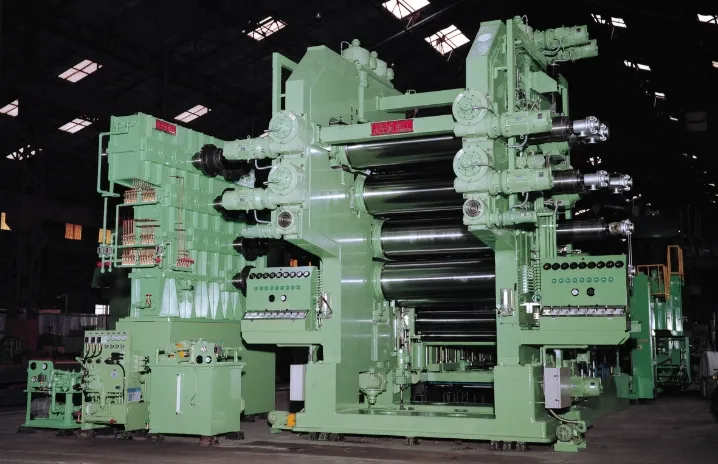

Calenders

Calendering was originally invented for rubberizing fabrics and has since evolved into a major industry, due to advances in the automotive manufacturing and the development of plastics.

Nowadays, calenders have come to be used in a wide range of industries such as the forming of rubber (tire, belts, etc.), plastics (film, sheets, leather, wall materials, tiles, etc.) and gasket sheets.

Nippon Roll calenders are designed and manufactured to perfectly match the customer's needs, such as increased product quality and precision.

Not only in Japan, but also abroad Nippon Roll calenders have acquired an excellent reputation and have been put to use in many countries in a wide range of applications.

⌀24” 6-Roll Calender

⌀24” 6-Roll Calender ⌀24” S-Type Calender

⌀24” S-Type Calender ⌀12”×L30” Inclined 3-Roll Calender

⌀12”×L30” Inclined 3-Roll Calender ⌀22”×L66” Inverted L-Type 4-Roll Calender

⌀22”×L66” Inverted L-Type 4-Roll Calender Model 150” Gasket Sheet Calender

Model 150” Gasket Sheet Calender

・Calender Specifications

| Calender Model | |

|---|---|

| Model | Roll Size - Dia×Length (Inch) |

| 8KC | 8×16-24 |

| 10KC | 10×20-30 |

| 12KC | 12×24-36 |

| 14KC | 14×28-42 |

| 16KC | 16×32-48 |

| 18KC | 18×36-54 |

| 20KC | 20×40-60 |

| 22KC | 22×44-66 |

| Calender Model | |

|---|---|

| Model | Roll Size - Dia×Length (Inch) |

| 24KC | 24×48-72 |

| 26KC | 26×52-78 |

| 28KC | 28×56-84 |

| 30KC | 30×60-90 |

| 32KC | 32×64-96 |

| 36KC | 36×72-108 |

| 40KC | 40×80-120 |

| Calender Model | |

|---|---|

| Model | Roll Size - Dia×Length (Inch) |

| 8KC | 8×16-24 |

| 10KC | 10×20-30 |

| 12KC | 12×24-36 |

| 14KC | 14×28-42 |

| 16KC | 16×32-48 |

| 18KC | 18×36-54 |

| 20KC | 20×40-60 |

| 22KC | 22×44-66 |

| 24KC | 24×48-72 |

| 26KC | 26×52-78 |

| 28KC | 28×56-84 |

| 30KC | 30×60-90 |

| 32KC | 32×64-96 |

| 36KC | 36×72-108 |

| 40KC | 40×80-120 |

- The roll length is subject to modification to best fit the application.

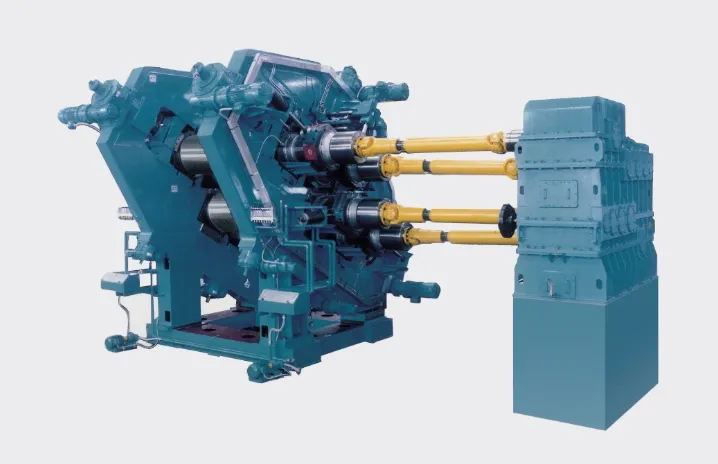

Mixing Mills

The mixing mill has been used in rubber and plastics processing since the early times of those industries.

It has the advantage of being simple, mechanically speaking, and the work in progress can be visually inspected at any point.

Nippon Roll mixing mills have been designed and manufactured to perform well even under the harshest conditions and this design and the basic construction have been well tested by thousands of successful installations for a variety of applications.

The mixing mill is also known as a sheeting, warming or refiner mill, depending on the respective use.

⌀26” Mixing Mill

⌀26” Mixing Mill ⌀28” Mixing Mill

⌀28” Mixing Mill ⌀22” Mixing Mill

⌀22” Mixing Mill

・Mixing Mill Specifications

| Model | |

|---|---|

| Model | Roll Size – Dia × Length (Inch) |

| 6KM | 6×12-18 |

| 8KM | 8×16-24 |

| 10KM | 10×20-30 |

| 12KM | 12×24-36 |

| 14KM | 14×28-42 |

| 16KM | 16×32-48 |

| 18KM | 18×36-54 |

| 20KM | 20×40-60 |

| Model | |

|---|---|

| Model | Roll Size – Dia × Length (Inch) |

| 22KM | 22×44-66 |

| 24KM | 24×48-72 |

| 26KM | 26×52-78 |

| 28KM | 28×56-84 |

| 30KM | 30×60-90 |

| 32KM | 32×64-96 |

| 34KM | 34×68-102 |

| Model | |

|---|---|

| Model | Roll Size – Dia × Length (Inch) |

| 6KM | 6×12-18 |

| 8KM | 8×16-24 |

| 10KM | 10×20-30 |

| 12KM | 12×24-36 |

| 14KM | 14×28-42 |

| 16KM | 16×32-48 |

| 18KM | 18×36-54 |

| 20KM | 20×40-60 |

| 22KM | 22×44-66 |

| 24KM | 24×48-72 |

| 26KM | 26×52-78 |

| 28KM | 28×56-84 |

| 30KM | 30×60-90 |

| 32KM | 32×64-96 |

| 34KM | 34×68-102 |

- The roll length is subject to modification to best fit the application.

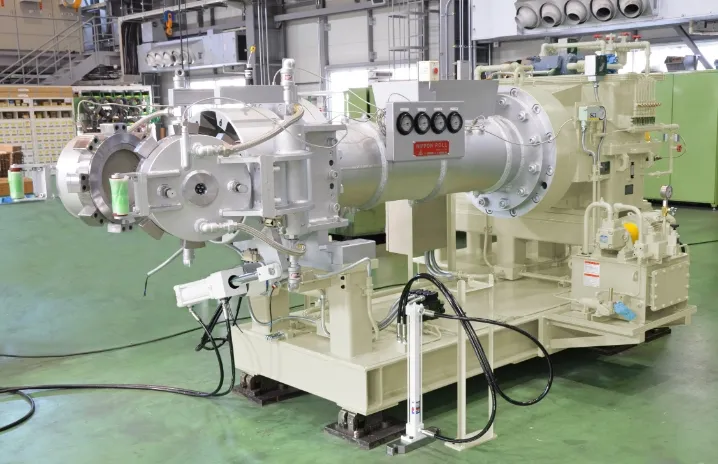

Intensive Mixers

High speed/high pressure type mixers have been introduced to a wide range of fields such as the kneading of various rubbers, and various plastics.

After the Banbury mixer had been developed as a machine for the kneading of rubber compounds,

Nippon Roll pioneered in Japan, developing the first viable, domestically produced mixer. The Nippon Roll internal mixer was given the name Intensive Mixer.

For this machine to perform well under all kinds of harsh conditions, robustness is put first in the design and manufacturing of the Intensive Mixer.

Today, Nippon Roll Intensive Mixers are used not only for the kneading of all types of rubber but also in all fields of plastics processing. Their excellent performance has earned the machines a high degree of trust both in Japan and abroad.

We pay strict attention to after-sales service and maintenance. Each customer is a VIP as far as Nippon Roll is concerned.

75L Slide-Door-Type Intensive Mixer

75L Slide-Door-Type Intensive Mixer 80L Drop-Door-Type Intensive Mixer

80L Drop-Door-Type Intensive Mixer 160L Drop-Door-Type Intensive Mixer

160L Drop-Door-Type Intensive Mixer

・Intensive Mixer Specifications

| Intensive Mixer Model | ||

|---|---|---|

| Model | Volume (ℓ) | Volume (ℓ) |

| 2-wing | 4-wing | |

| 2KV | 2.3 | 1.6 |

| 5KV | 5.7 | 4.1 |

| 10KV | 10.4 | 9.3 |

| 20KV | 23 | 20.2 |

| 35KV | 39.8 | 34.8 |

| 50KV | 51 | 48 |

| 75KV | 81 | 71 |

| 80KV | 82 | 78 |

| Intensive Mixer Model | ||

|---|---|---|

| Model | Volume (ℓ) | Volume (ℓ) |

| 2-wing | 4-wing | |

| 100KV | 107 | 100 |

| 120KV | 126 | 118 |

| 140KV | 145 | 121 |

| 160KV | 151 | 131 |

| 180KV | 181 | 163 |

| 200KV | 200 | 177 |

| 230KV | 224 | 193 |

| 270KV | 278 | 243 |

| Intensive Mixer Model | ||

|---|---|---|

| Model | Volume (ℓ) | Volume (ℓ) |

| 2-wing | 4-wing | |

| 2KV | 2.3 | 1.6 |

| 5KV | 5.7 | 4.1 |

| 10KV | 10.4 | 9.3 |

| 20KV | 23 | 20.2 |

| 35KV | 39.8 | 34.8 |

| 50KV | 51 | 48 |

| 75KV | 81 | 71 |

| 80KV | 82 | 78 |

| 100KV | 107 | 100 |

| 120KV | 126 | 118 |

| 140KV | 145 | 121 |

| 160KV | 151 | 131 |

| 180KV | 181 | 163 |

| 200KV | 200 | 177 |

| 230KV | 224 | 193 |

| 270KV | 278 | 243 |

- Chamber volume varies with tip clearance

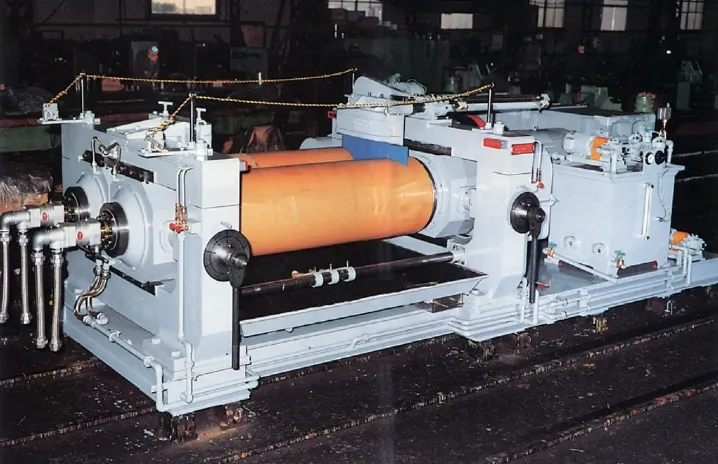

Strainers

Primarily constructed to remove any lint, gravel particles, iron powder, wood chips etc., that have mixed into the plastic resin and rubber during mixing and kneading processes, Nippon Roll strainer extruders can carry out continued kneading and extruding.

Being mounted in its entirety on a single bed, this machine can easily be installed and relocated.

Model 8 Strainer

Model 8 Strainer Model 10 Strainer

Model 10 Strainer Model 10 Strainer

Model 10 Strainer

・Strainer Specifications

| Strainer Model | |

|---|---|

| Strainer Model | Screw Dia (mm) |

| 6KS | 150 |

| 8KS | 200 |

| 10KS | 254 |

| 12KS | 300 |

Inquiries to the Machinery Roll Business Division

If you have any questions or inquiries about the Machinery Roll Business Division, please feel free to contact us.

- Inquiries via WebTo the Inquiry Form

- Inquiries by Phone03-3878-6661Reception hours / Weekdays 9:00 AM to 5:00 PM